Isobaric expansion technology

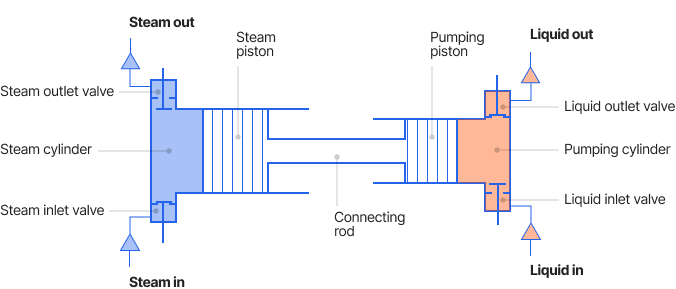

The Isobaric Expansion (IE) process is an alternative to conventional processes commonly observed in contemporary heat engines, which involves a pressure decrease throughout the cycle. The basic principle of the IE engine is to generate useful power at a constant high cycle pressure and perform the cycle compression stage at a constant low cycle pressure. As a result, the engine’s design becomes simplified, and the contribution of thermal and mechanical losses to the overall cycle efficiency can be significantly reduced compared to conventional heat engines.

IE engines are the oldest types of heat engines, dating back to the beginning of the Industrial Revolution. These machines were later replaced by more efficient, well-known water steam expansion machines such as piston steam engines and turbines. However, modern trends in energy sources used and energy conversion have led to the revival of this old technology. Over the past few decades, many IE engines have been proposed and studied again under different names and for different applications.

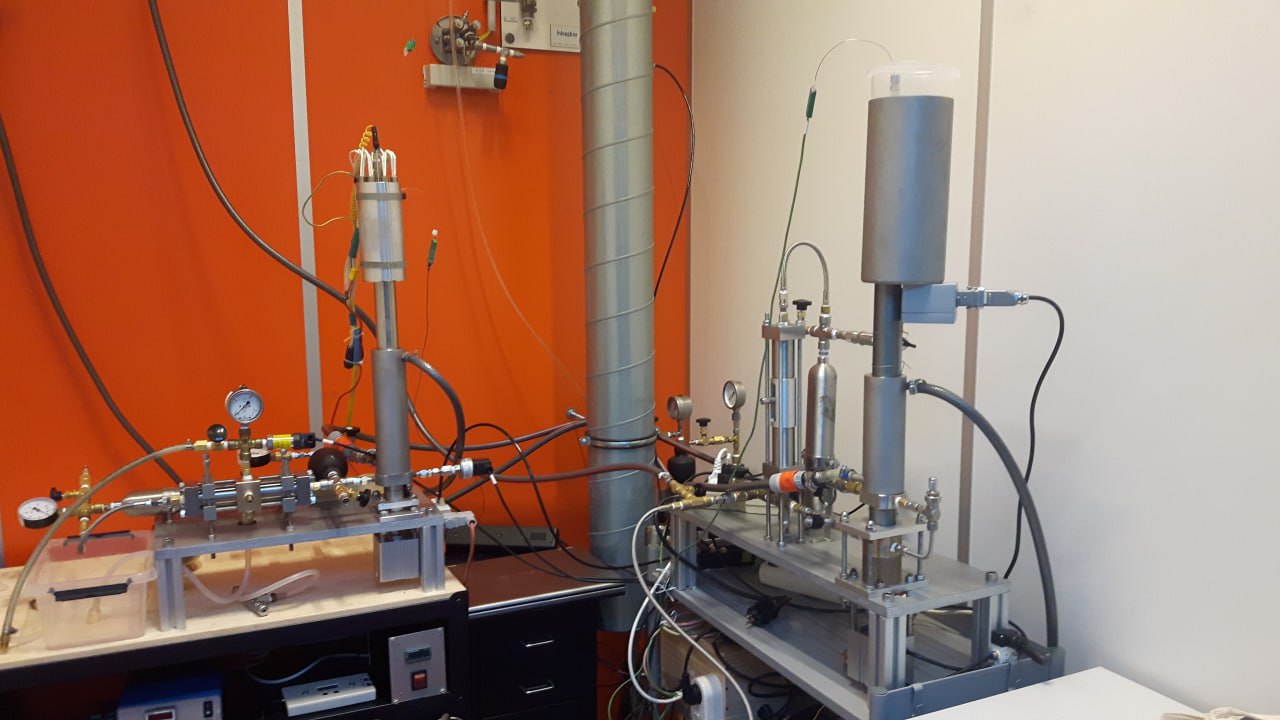

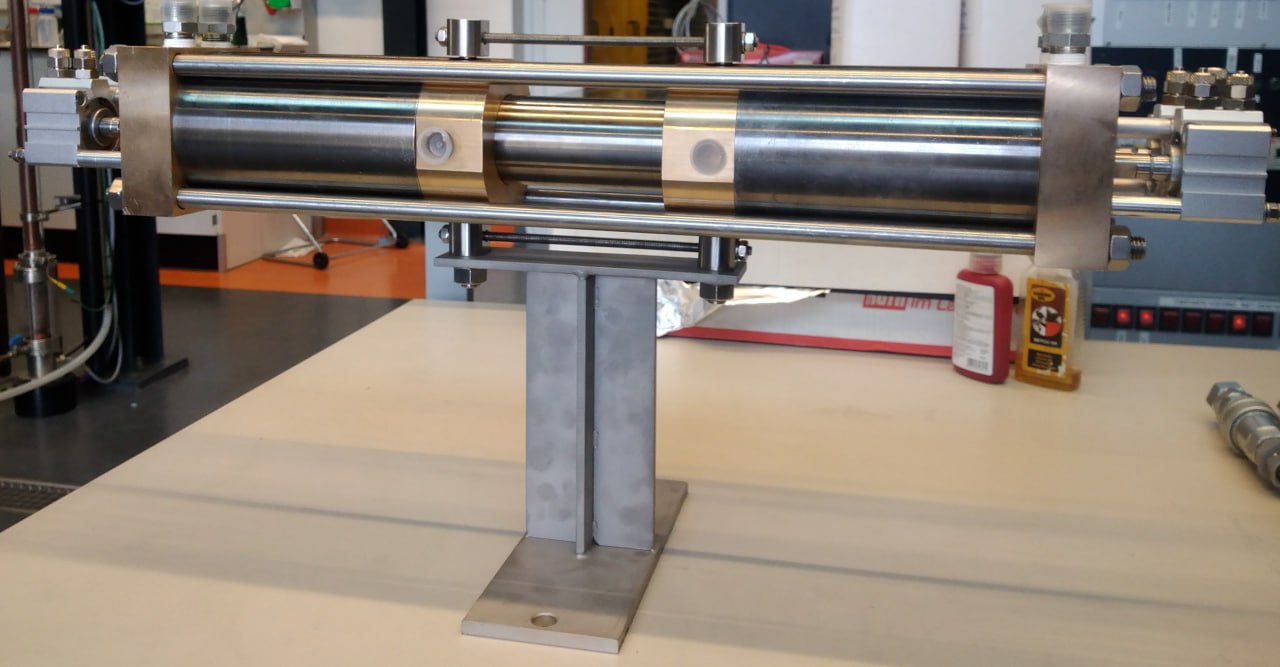

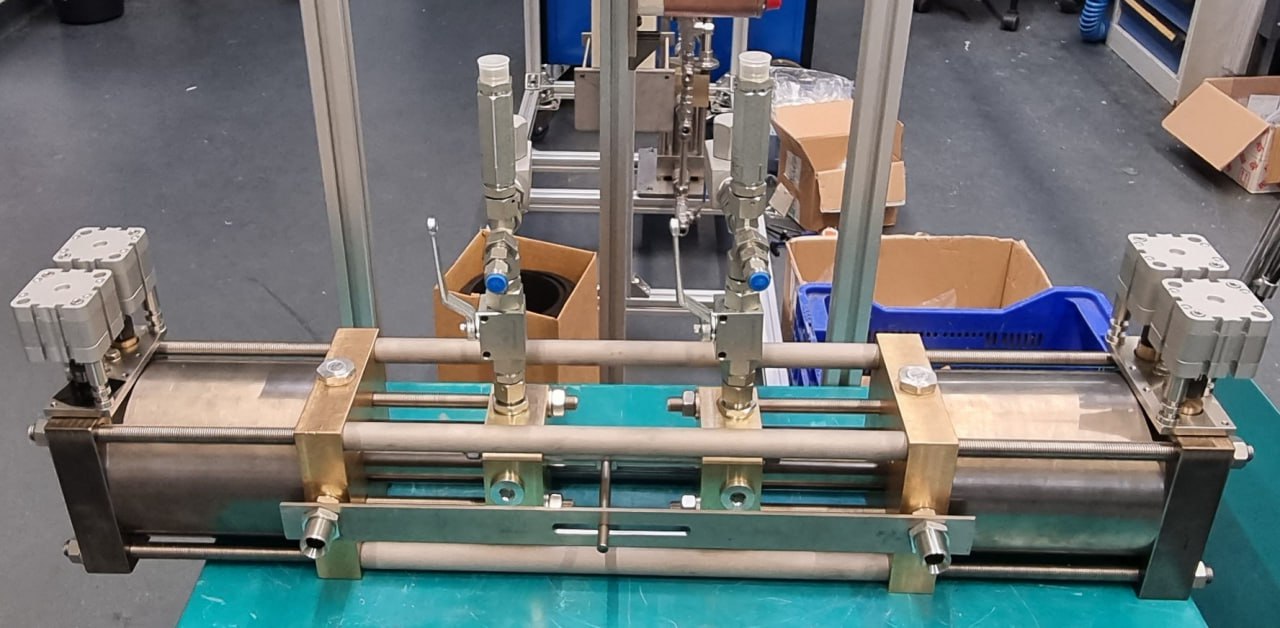

IE engines offered by Encontech directly convert heat into mechanical energy in a convenient hydraulic or pneumatic form, which can be readily converted into various other forms of energy. Using a differential piston arrangement (a combination of two pistons with different diameters), the IE engine can deliver any pressure of the pumped/compressed liquid or gas. These systems are almost noiseless, can be fully balanced, and have a simple, reliable, and inexpensive design. Some versions of the IE engines avoid typical technical problems associated with well-known thermal-energy-driven systems, such as failure of sealing components, lubrication, and wear.

Isobaric expansion technology presents a promising solution for recovering and utilizing low-grade heat in mini- and medium-scale applications. It is very versatile, easily scalable and reproducible in all industries where there is a temperature difference > 20 °C. Among the notable applications, IE engines show great promise as vapor-driven pumps and compressors due to their straightforward design. In such applications, heat can be efficiently utilized for direct pumping and compression without the intermediate steps of generating shaft power or electricity, subsequent transmission, and reconversion to mechanical energy, as commonly practiced in current industrial processes. These methods hold significant potential for replacing primary fossil energy sources with readily available low-grade heat, even at temperatures below 100 °C. High pressure pumps for water desalination, compression of hydrogen, air, ethylene and other gasses at high pressure and heat engines for generating mechanical energy (electricity) using geothermal, biomass and solar energy, waste heat of diesel engines, computer data centers as well as of SOFCs and LT-PEM fuel cells are examples of promising applications.

The current status of IE technology and essential modifications to make IE machines competitive and cost-effective alternatives to state-of-the-art heat conversion technologies are presented in or publications:

- Glushenkov, M.; Kronberg, A.; Knoke, T.; Kenig, E.Y. Isobaric Expansion Engines: New Opportunities in Energy Conversion for Heat Engines, Pumps and Compressors. Energies 2018, 11, 154. https://doi.org/10.3390/en11010154.

- Glushenkov, M.; Kronberg, A. Experimental study of an isobaric expansion engine-pump—Proof of concept. Appl. Therm. Eng. 2022, 212, 118521. https://doi.org/10.1016/j.applthermaleng.2022.118521.

Roosjen, S.; Glushenkov, M.; Kronberg, A.; Kersten, S. Waste Heat Recovery Systems with Isobaric Expansion Technology Using Pure and Mixed Working Fluids. Energies 2022, 15, 5265. https://doi.org/10.3390/en15145265. - Kronberg, A.; Glushenkov, M.; Roosjen, S.; Kersten, S. Isobaric expansion engine-compressors: Efficiency of the simplest reciprocating vapor driven compressors. Energies 2022, 15, 5028. https://doi.org/10.3390/en15145028.